- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

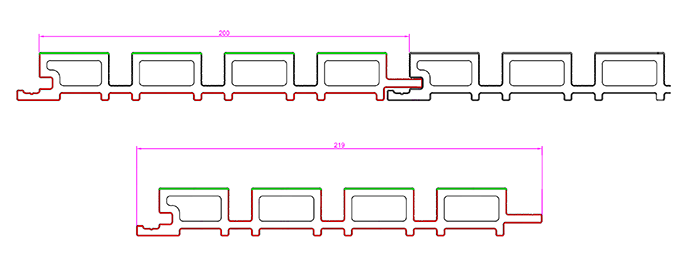

>> Side View:

WPC (Wood-Plastic Composite) co-extrusion wall panels, when used to decorate the exterior of buildings, can inject new vitality and appearance into the structure, extending its service life and thereby enhancing the overall value of the building. Additionally, they improve the building's thermal insulation, soundproofing, and natural lighting performance. WPC co-extrusion wall panels are resistant to deformation, moisture, and insects, and possess certain eco-friendly properties. With their elegant and versatile design, rich color options, and wide range of applications, they serve as an ideal substitute for traditional preservative-treated wood.

Our WPC co-extrusion wall panels utilize advanced co-extrusion technology, where the surface layer forms a high-density protective coating through the co-extrusion process. This gives the panels exceptional wear resistance, UV resistance, and anti-aging properties, ensuring long-lasting use without fading or deformation. The dual-color design enhances the product's visual appeal, making it even more attractive.

>> Advantage

Eco - friendly and healthy: WPC boards are primarily made from wood fibers, plastics, and a small amount of additives. They are recyclable, which reduces the felling of natural timber, contributing to environmental protection.

Waterproof and moisture - resistant: Unlike traditional wooden boards, WPC boards have excellent waterproof properties. They can effectively resist water intrusion, remaining unaffected by moisture - induced deformation or decay.

Corrosion and pest - resistant: Thanks to the addition of plastic components, WPC boards possess anti - corrosion and anti - pest properties that natural wood lacks. Without the need for chemical preservatives, they can effectively prevent damage from mold, termites, and other pests, significantly extending their service life.

Good mechanical properties: WPC boards combine the advantages of wood and plastic, boasting high strength, hardness, and impact resistance. They are less prone to cracking or breaking, capable of withstanding a certain amount of weight and external forces.

Easy to process: WPC boards can be processed like wood, allowing operations such as sawing, planing, nailing, and drilling. This convenience enables construction workers to create various shapes and installations according to specific requirements. Additionally, through hot - pressing and other processes, they can be made into boards with various surface textures and colors, satisfying different decorating styles.

Low - maintenance: WPC boards have a smooth surface, making them less likely to accumulate dust and dirt. Daily cleaning only requires wiping with a damp cloth. There is no need for regular maintenance tasks such as waxing or painting, saving both maintenance costs and time.

>> Parameter

Name | WPC CO-extrusion Wall panel |

Component | HDPE,Wood powder,Additives |

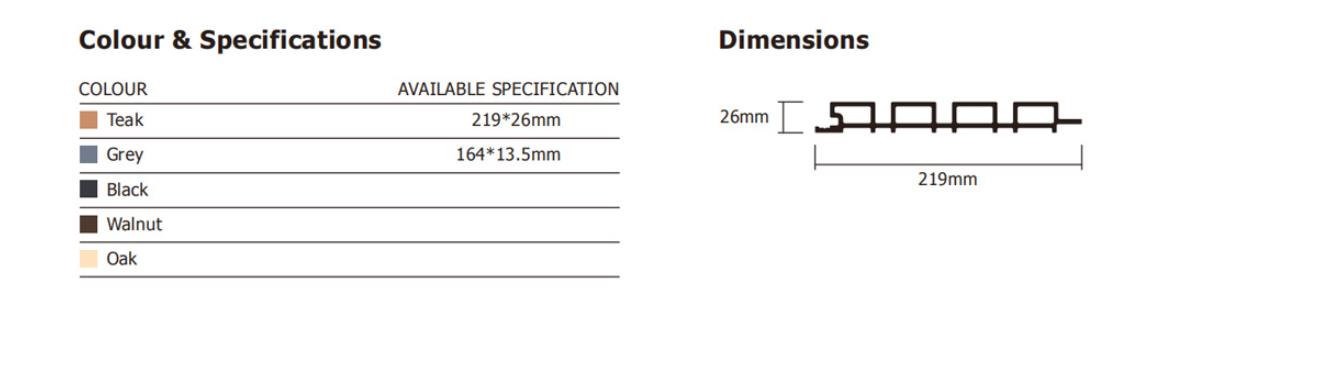

Specification | 219X26mm |

Structure | 4holes |

Length | 2.2m,2.2m,5.4m |

Surface treatment | Sanded&Brushed |

Regular color | Teak,Walnut,Grey ,Black ,Oak etc. |

>> Application Scenarios

Wood-plastic composite (WPC) Great Wall panels, known for their environmental friendliness, durability, and aesthetic appeal, are widely utilized across various sectors. In the field of architecture, they are commonly used for exterior wall decoration of residential and commercial buildings. In landscape gardening, they are suitable for facilities such as planters. In municipal engineering, they can be employed for fences in parks and squares, offering low maintenance costs and long-lasting durability. Additionally, they are used for decorative protection in transportation hubs, the construction of agricultural facilities, and customized applications such as billboards and display stands.

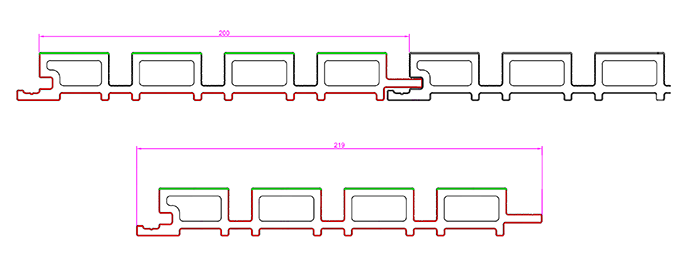

>> Side View:

WPC (Wood-Plastic Composite) co-extrusion wall panels, when used to decorate the exterior of buildings, can inject new vitality and appearance into the structure, extending its service life and thereby enhancing the overall value of the building. Additionally, they improve the building's thermal insulation, soundproofing, and natural lighting performance. WPC co-extrusion wall panels are resistant to deformation, moisture, and insects, and possess certain eco-friendly properties. With their elegant and versatile design, rich color options, and wide range of applications, they serve as an ideal substitute for traditional preservative-treated wood.

Our WPC co-extrusion wall panels utilize advanced co-extrusion technology, where the surface layer forms a high-density protective coating through the co-extrusion process. This gives the panels exceptional wear resistance, UV resistance, and anti-aging properties, ensuring long-lasting use without fading or deformation. The dual-color design enhances the product's visual appeal, making it even more attractive.

>> Advantage

Eco - friendly and healthy: WPC boards are primarily made from wood fibers, plastics, and a small amount of additives. They are recyclable, which reduces the felling of natural timber, contributing to environmental protection.

Waterproof and moisture - resistant: Unlike traditional wooden boards, WPC boards have excellent waterproof properties. They can effectively resist water intrusion, remaining unaffected by moisture - induced deformation or decay.

Corrosion and pest - resistant: Thanks to the addition of plastic components, WPC boards possess anti - corrosion and anti - pest properties that natural wood lacks. Without the need for chemical preservatives, they can effectively prevent damage from mold, termites, and other pests, significantly extending their service life.

Good mechanical properties: WPC boards combine the advantages of wood and plastic, boasting high strength, hardness, and impact resistance. They are less prone to cracking or breaking, capable of withstanding a certain amount of weight and external forces.

Easy to process: WPC boards can be processed like wood, allowing operations such as sawing, planing, nailing, and drilling. This convenience enables construction workers to create various shapes and installations according to specific requirements. Additionally, through hot - pressing and other processes, they can be made into boards with various surface textures and colors, satisfying different decorating styles.

Low - maintenance: WPC boards have a smooth surface, making them less likely to accumulate dust and dirt. Daily cleaning only requires wiping with a damp cloth. There is no need for regular maintenance tasks such as waxing or painting, saving both maintenance costs and time.

>> Parameter

Name | WPC CO-extrusion Wall panel |

Component | HDPE,Wood powder,Additives |

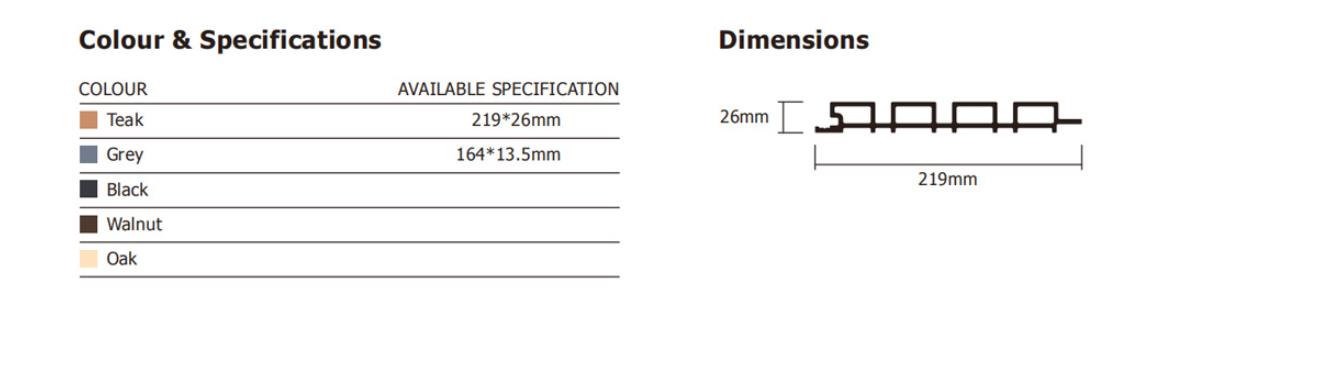

Specification | 219X26mm |

Structure | 4holes |

Length | 2.2m,2.2m,5.4m |

Surface treatment | Sanded&Brushed |

Regular color | Teak,Walnut,Grey ,Black ,Oak etc. |

>> Application Scenarios

Wood-plastic composite (WPC) Great Wall panels, known for their environmental friendliness, durability, and aesthetic appeal, are widely utilized across various sectors. In the field of architecture, they are commonly used for exterior wall decoration of residential and commercial buildings. In landscape gardening, they are suitable for facilities such as planters. In municipal engineering, they can be employed for fences in parks and squares, offering low maintenance costs and long-lasting durability. Additionally, they are used for decorative protection in transportation hubs, the construction of agricultural facilities, and customized applications such as billboards and display stands.