- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

YK-D07

>> Side View:

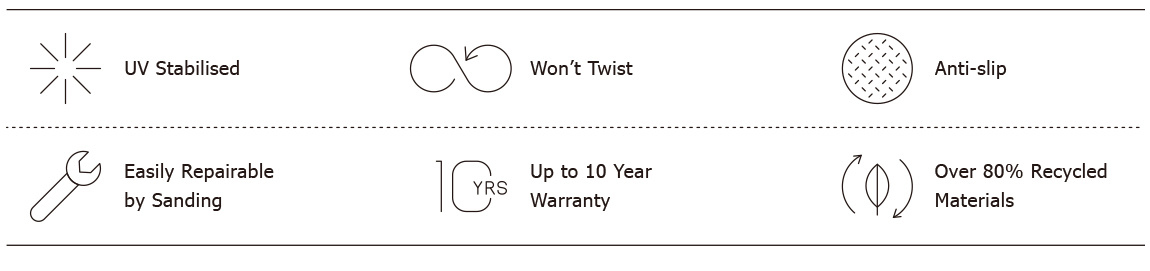

Wood-plastic composite materials (also known as ecological wood) are a new type of environmentally friendly building decoration material. They are made by mixing wood fibers or wood powder with plastic and then processing them into boards or profiles through plastic processing techniques such as extrusion, molding, and injection molding. This composite profile combines environmental protection features such as zero formaldehyde, anti-insect, anti-termite, wear-resistant and pressure-resistant, waterproof and moisture-proof, sun-proof and anti-corrosion. Its anti-slip and fireproof design further endows it with the advantages of safety and durability.

Our wood plastic flooring panels are made from natural wood powder, HDPE recycled materials, and functional additives. They are formaldehyde-free, insect-proof, ant-proof, wear-resistant, pressure-resistant, waterproof, moisture-proof, sun-proof, and anti-corrosive. The slip-resistant and fire-resistant design ensures safety and durability.

>> Product Benefits

Features of Wood-Plastic Composite hollow decking:

1. Water Resistance: One of the standout features of WPC flooring is its high resistance to water. It's designed to withstand spills, moisture, and even flooding, making it an ideal choice for areas prone to humidity or wetness

2. Durability: WPC flooring is known for its durability. The composite material, which typically includes wood fibers, plastic (often PVC), and additives, creates a strong and resilient floor that can handle heavy foot traffic, scratches, and dents better than many traditional hardwood floors.

3. Ease of Installation: speeds up the installation process for professionals.

4. Comfort Underfoot: Unlike hard surfaces like traditional tiles, WPC flooring offers a slight cushioning effect underfoot due to its layered construction.

5. Realistic Wood Look: Advanced printing technologies enable WPC flooring to mimic the appearance of natural wood grains, textures, and colors exceptionally well. This means you can achieve the elegant look of hardwood without the maintenance hassles or cost.

6. Low Maintenance: Cleaning and maintaining WPC flooring is relatively simple. Regular sweeping or vacuuming to remove dust and debris, followed by damp mopping with a mild cleaner, is usually sufficient to keep it looking new.

7. Hypoallergenic: The surface of WPC flooring is non-porous, which prevents the accumulation of dust, pollen, and other allergens, creating a healthier environment for those with allergies or asthma.

8. Variety of Options: WPC flooring comes in a wide range of styles, colors, and finishes, allowing homeowners to choose a design that fits their aesthetic preferences and interior decor.

9. Environmentally Friendly: While the environmental impact can vary depending on the manufacturing process and materials used, some WPC products incorporate recycled plastics and wood fibers, contributing to sustainability efforts.

>> Parameter

Product Name | WPC Hollow Decking |

Constituent | HDPE,Wood powder,Additives |

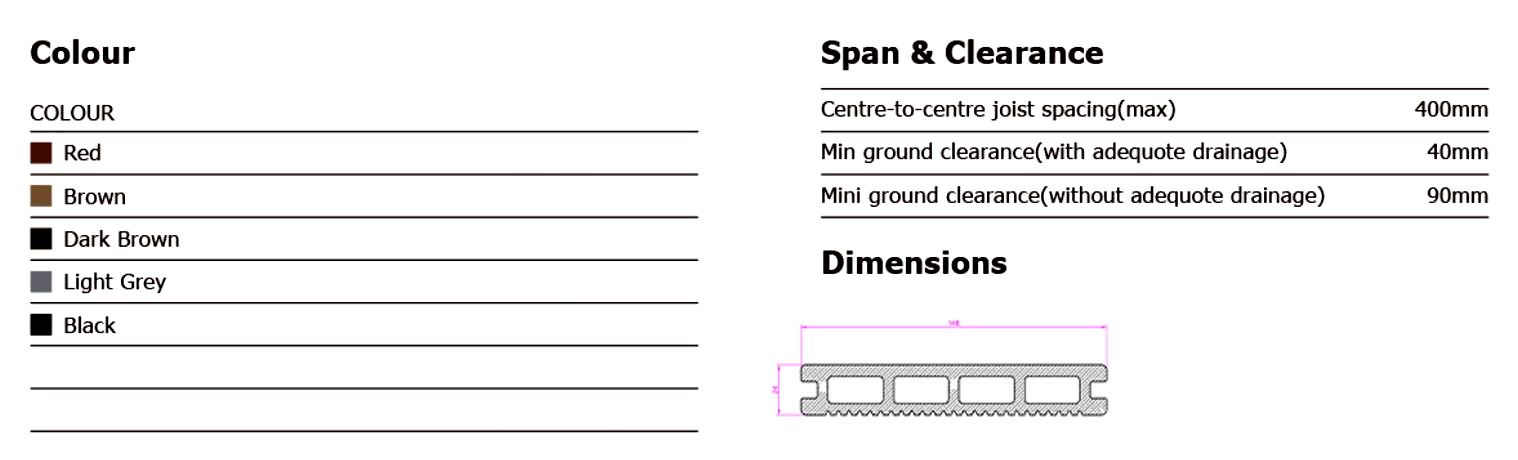

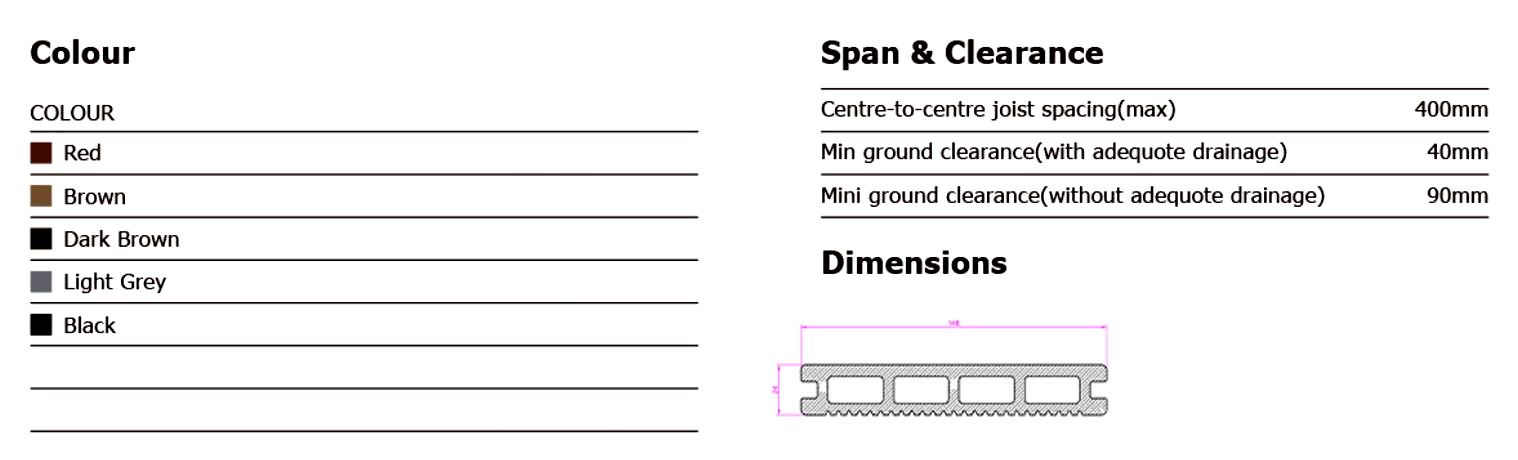

Dimension | 146×24mm |

Length | 2.2m,2.2m,5.4m and can be customized. |

Surface treatment | Sanded&Brushed |

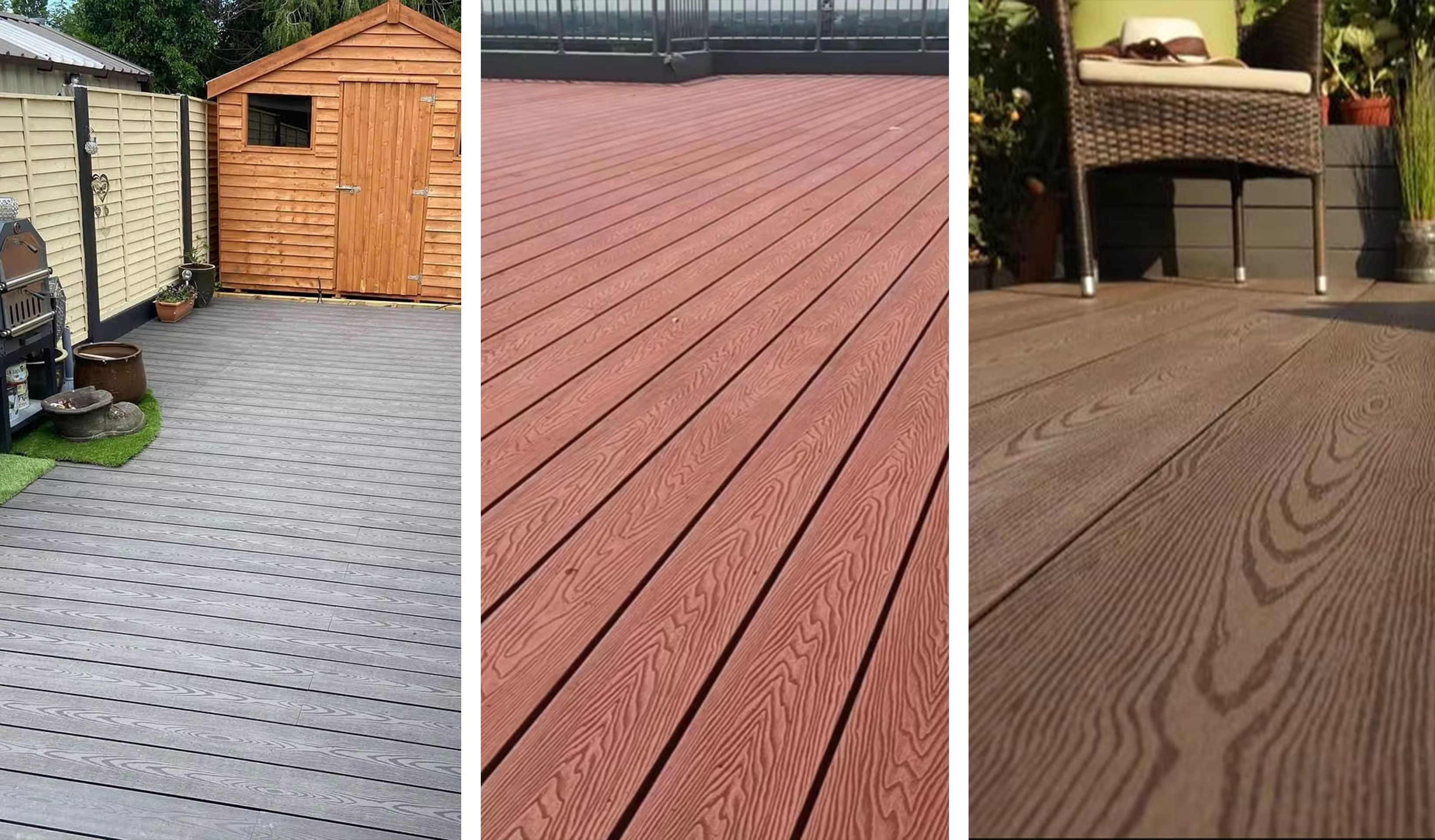

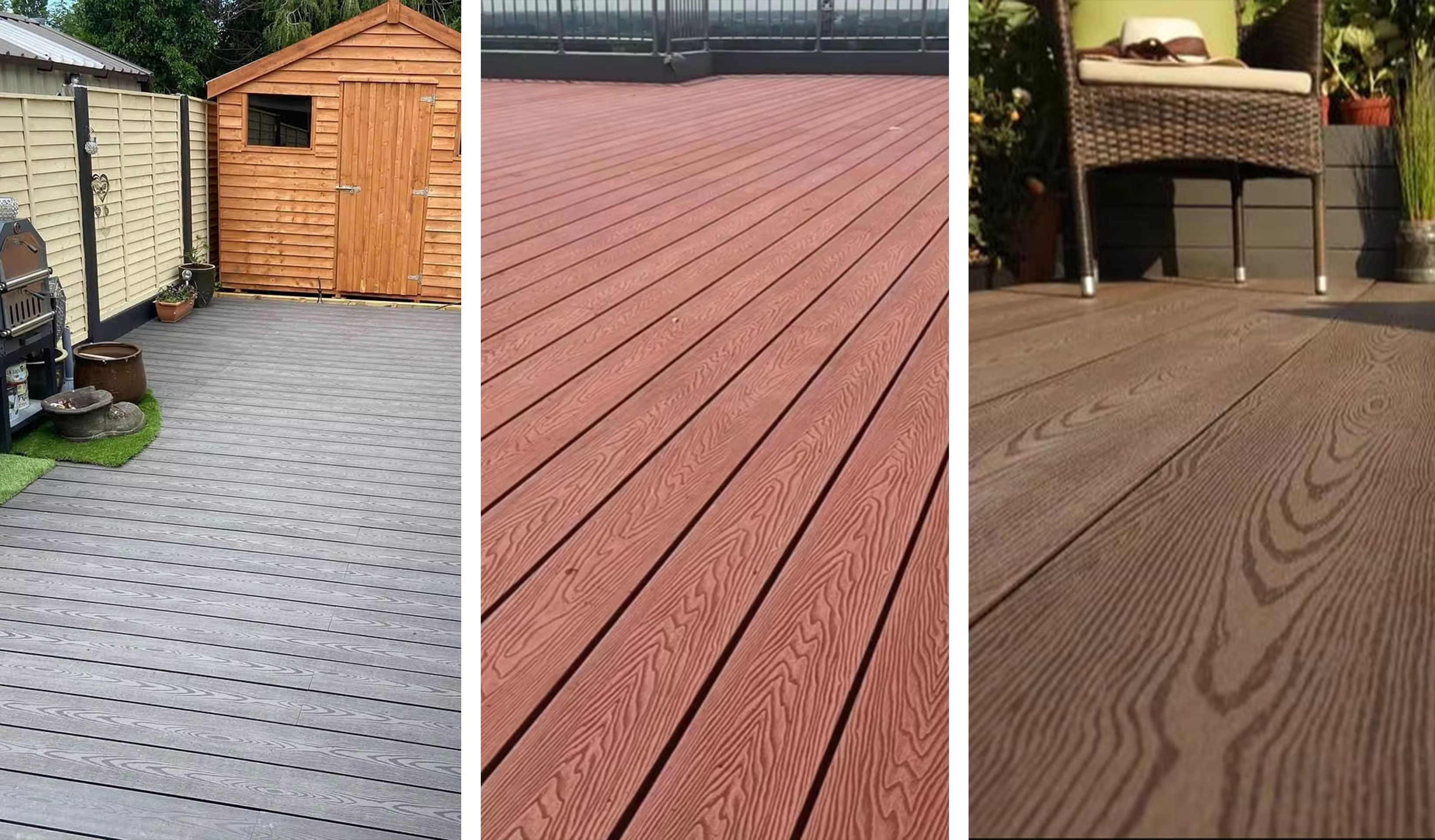

Our Colors | Red,Brown,Dark Brown,Light Grey,Black,etc |

>> Application Scenarios

WPC (Wood Plastic Composite) flooring is widely applicable due to its durability, environmental friendliness, and ease of maintenance

Courtyard

Chinese or Western-style courtyards, with their waterproof and moisture-proof features, are suitable for outdoor environments.

Garden

The wood grain texture blends naturally with plants, and it is more resistant to decay and insects than natural wood.

Terrace (Rooftop terrace

The UV-resistant formula prevents fading by sunlight, and the lightweight design reduces the load on buildings.

Park

High durability requirements in public areas, anti-slip surfaces enhance safety.

Patio (Courtyard platform

The outdoor furniture display area has strong pressure resistance and is not prone to depression.

Corridor

In high-flow areas, lock buckle splicing is used to prevent edge warping and deformation.

>> Side View:

Wood-plastic composite materials (also known as ecological wood) are a new type of environmentally friendly building decoration material. They are made by mixing wood fibers or wood powder with plastic and then processing them into boards or profiles through plastic processing techniques such as extrusion, molding, and injection molding. This composite profile combines environmental protection features such as zero formaldehyde, anti-insect, anti-termite, wear-resistant and pressure-resistant, waterproof and moisture-proof, sun-proof and anti-corrosion. Its anti-slip and fireproof design further endows it with the advantages of safety and durability.

Our wood plastic flooring panels are made from natural wood powder, HDPE recycled materials, and functional additives. They are formaldehyde-free, insect-proof, ant-proof, wear-resistant, pressure-resistant, waterproof, moisture-proof, sun-proof, and anti-corrosive. The slip-resistant and fire-resistant design ensures safety and durability.

>> Product Benefits

Features of Wood-Plastic Composite hollow decking:

1. Water Resistance: One of the standout features of WPC flooring is its high resistance to water. It's designed to withstand spills, moisture, and even flooding, making it an ideal choice for areas prone to humidity or wetness

2. Durability: WPC flooring is known for its durability. The composite material, which typically includes wood fibers, plastic (often PVC), and additives, creates a strong and resilient floor that can handle heavy foot traffic, scratches, and dents better than many traditional hardwood floors.

3. Ease of Installation: speeds up the installation process for professionals.

4. Comfort Underfoot: Unlike hard surfaces like traditional tiles, WPC flooring offers a slight cushioning effect underfoot due to its layered construction.

5. Realistic Wood Look: Advanced printing technologies enable WPC flooring to mimic the appearance of natural wood grains, textures, and colors exceptionally well. This means you can achieve the elegant look of hardwood without the maintenance hassles or cost.

6. Low Maintenance: Cleaning and maintaining WPC flooring is relatively simple. Regular sweeping or vacuuming to remove dust and debris, followed by damp mopping with a mild cleaner, is usually sufficient to keep it looking new.

7. Hypoallergenic: The surface of WPC flooring is non-porous, which prevents the accumulation of dust, pollen, and other allergens, creating a healthier environment for those with allergies or asthma.

8. Variety of Options: WPC flooring comes in a wide range of styles, colors, and finishes, allowing homeowners to choose a design that fits their aesthetic preferences and interior decor.

9. Environmentally Friendly: While the environmental impact can vary depending on the manufacturing process and materials used, some WPC products incorporate recycled plastics and wood fibers, contributing to sustainability efforts.

>> Parameter

Product Name | WPC Hollow Decking |

Constituent | HDPE,Wood powder,Additives |

Dimension | 146×24mm |

Length | 2.2m,2.2m,5.4m and can be customized. |

Surface treatment | Sanded&Brushed |

Our Colors | Red,Brown,Dark Brown,Light Grey,Black,etc |

>> Application Scenarios

WPC (Wood Plastic Composite) flooring is widely applicable due to its durability, environmental friendliness, and ease of maintenance

Courtyard

Chinese or Western-style courtyards, with their waterproof and moisture-proof features, are suitable for outdoor environments.

Garden

The wood grain texture blends naturally with plants, and it is more resistant to decay and insects than natural wood.

Terrace (Rooftop terrace

The UV-resistant formula prevents fading by sunlight, and the lightweight design reduces the load on buildings.

Park

High durability requirements in public areas, anti-slip surfaces enhance safety.

Patio (Courtyard platform

The outdoor furniture display area has strong pressure resistance and is not prone to depression.

Corridor

In high-flow areas, lock buckle splicing is used to prevent edge warping and deformation.