- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

YK-D01

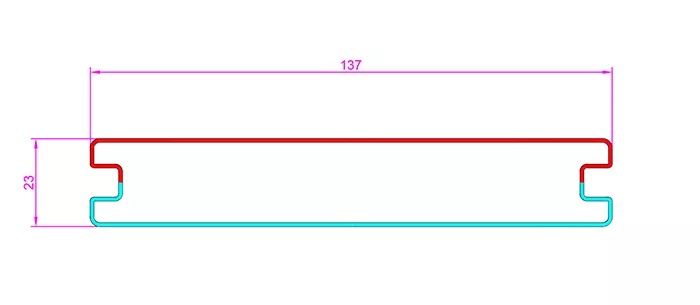

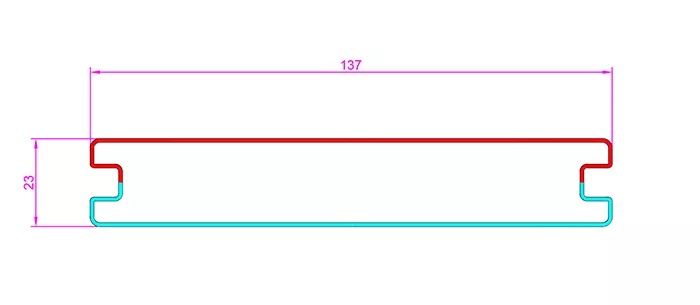

>> Side View:

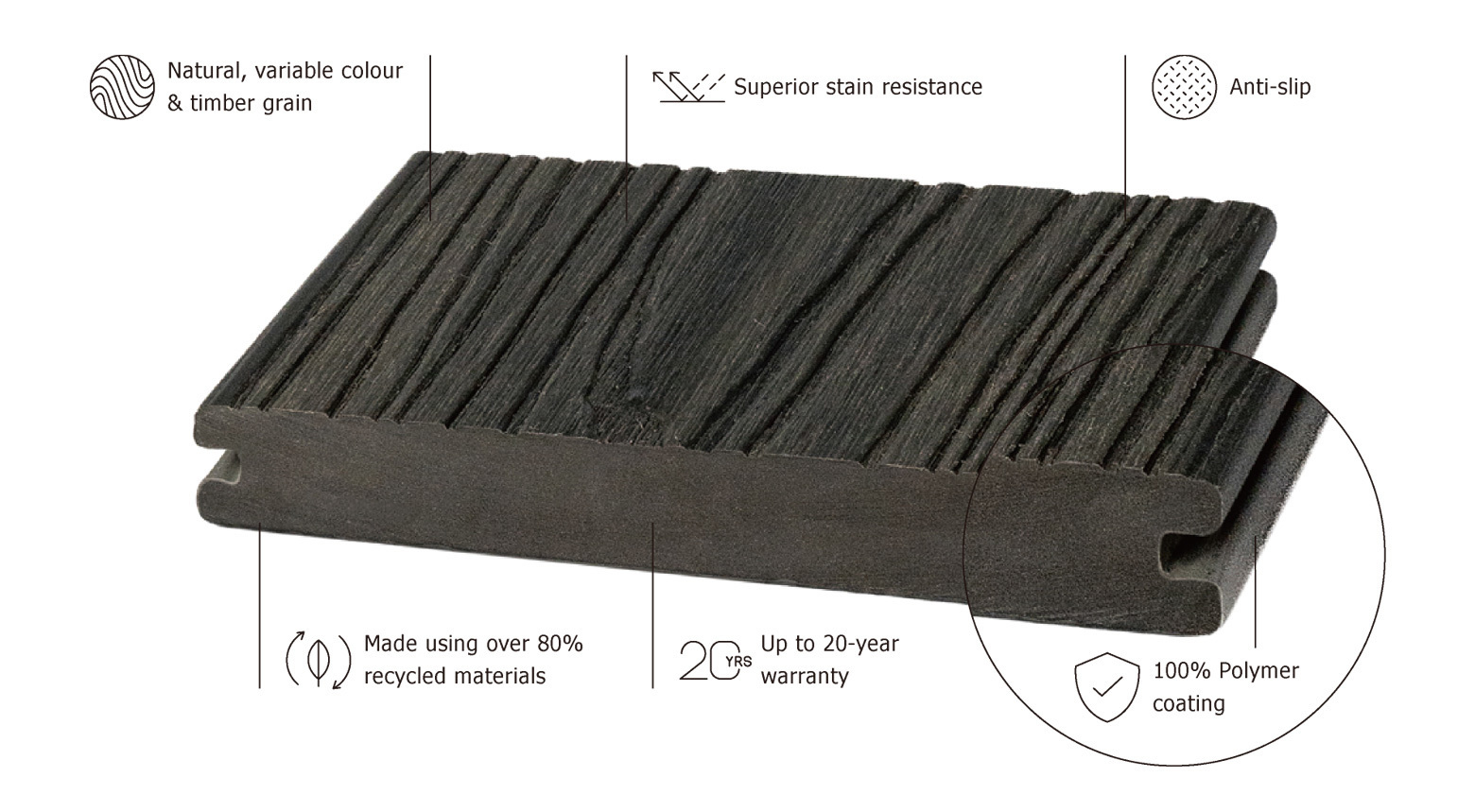

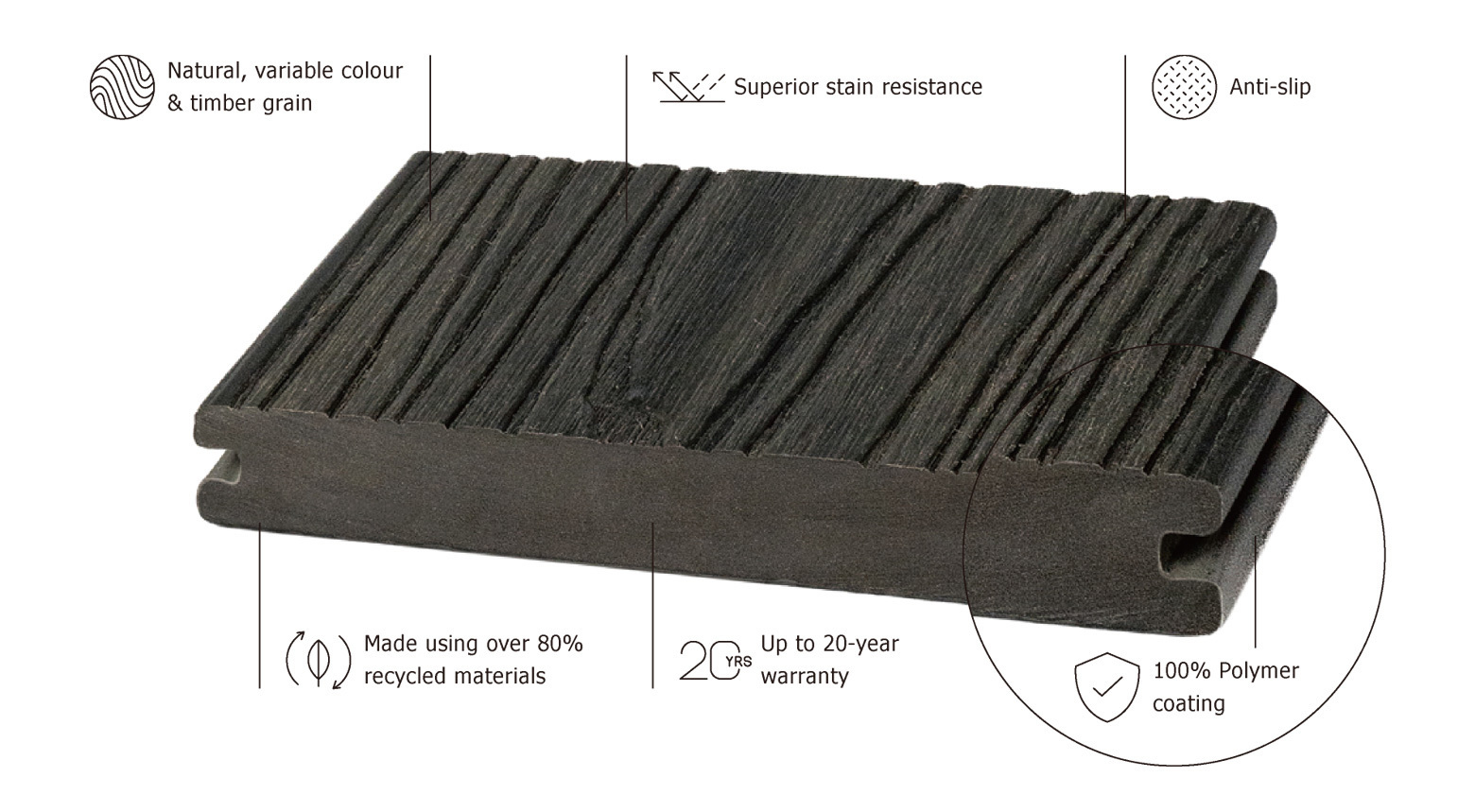

WPC outdoor decking, also known as wood-plastic composite decking, is primarily made from wood flour, PE powder, and other additives. This type of board is produced through a series of processes including raw material mixing, extrusion molding, cooling and shaping, surface treatment, and processing. The co-extruded WPC products feature the natural color variations and grain of real wood, enhanced by a 360-degree full coverage of a polymer protective layer, which significantly improves the product's strength. Moreover, it ensures that the product can withstand the harsh conditions of outdoor environments, avoiding the various shortcomings associated with traditional solid wood and pressure-treated wood products.

Our wood-plastic co-extruded solid wood flooring is all covered with a 360-degree high-molecular composite protective layer technology. Avoid the defects of traditional solid wood such as mold, water cracking, discoloration, deformation and warping. The embossing process of 3D wood grain finish is not "thermal printing", but "embossing", so this wood grain can last for at least 8 to 10 years. It retains the plastic shell, so the surface is harder and absorbs less water. Because the surface is hard, scratches will not take effect on it

>> Product Benefits

Features of Wood-Plastic Co-Extruded Solid Flooring:

| Feature | Description |

|---|---|

| Dimensionally Stable | Long-lasting with a natural feel. |

| Temperature & Weather Resistant | Stable across a wide temperature range and resistant to weather conditions. |

| High Impact Resistance | Durable and able to withstand strong impacts. |

| Eco-Friendly | Environmentally friendly and recyclable. |

| Aesthetic Variety | Available in a wide range of colors to meet diverse design and aesthetic needs. |

| Easy Installation | Simple and straightforward to install. |

| Decay & Crack Resistant | Resistant to decay and cracking. |

| Moisture-Proof | Protects against moisture damage. |

>> Parameter

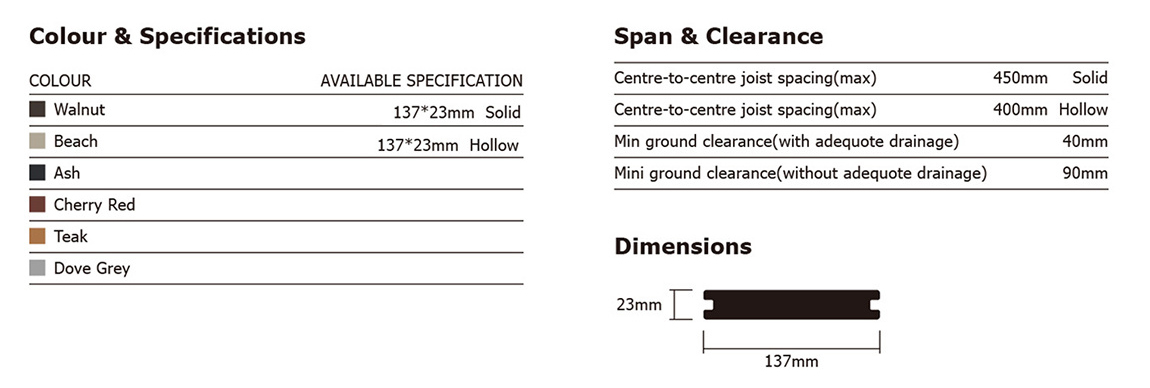

Product Name | WPC Co-Extrusion Soild Decking |

Constituent | HDPE,Wood powder,Additives |

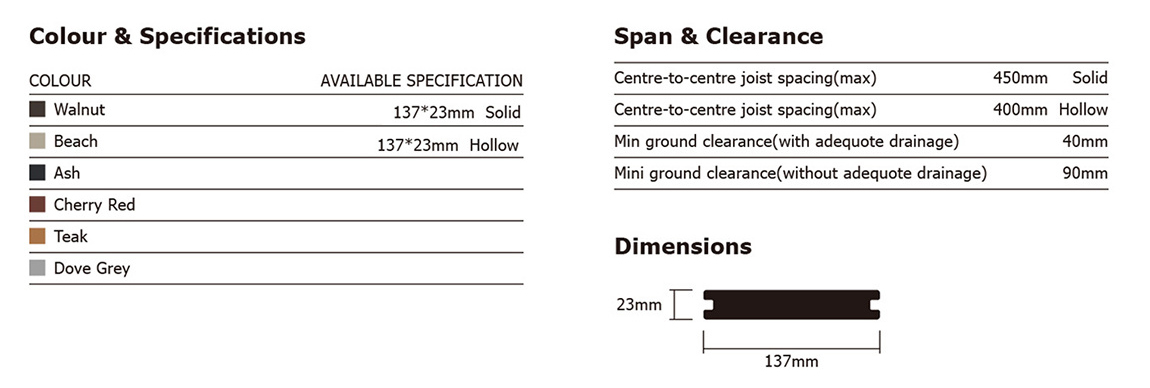

Dimension | 137×23mm |

Length | 2.2m,2.2m,5.4m and can be customized. |

Surface treatment | Sanded&Brushed |

Our Colors | Walnut,beach,ash,cherryred,teak,dove grey,etc. |

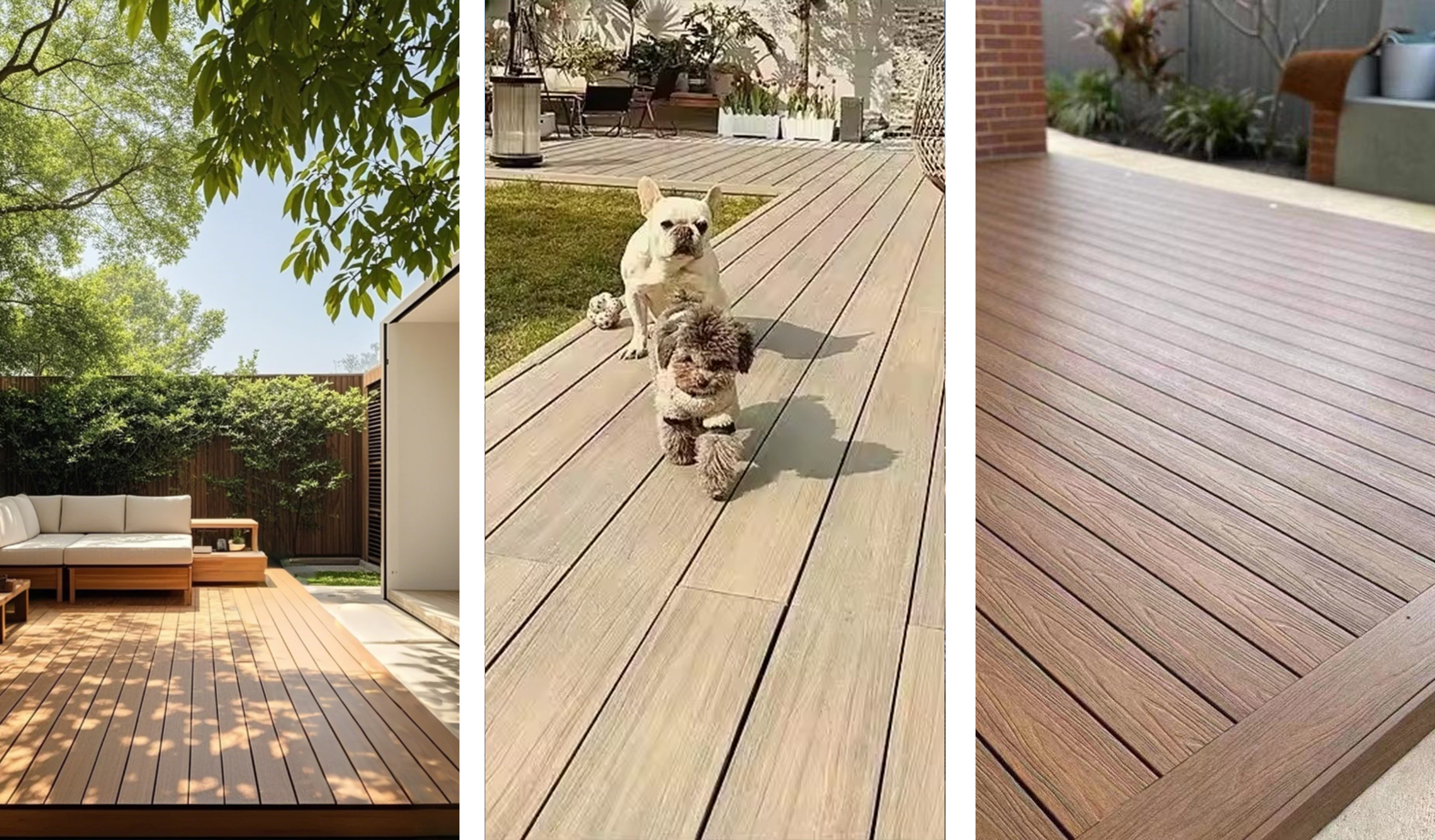

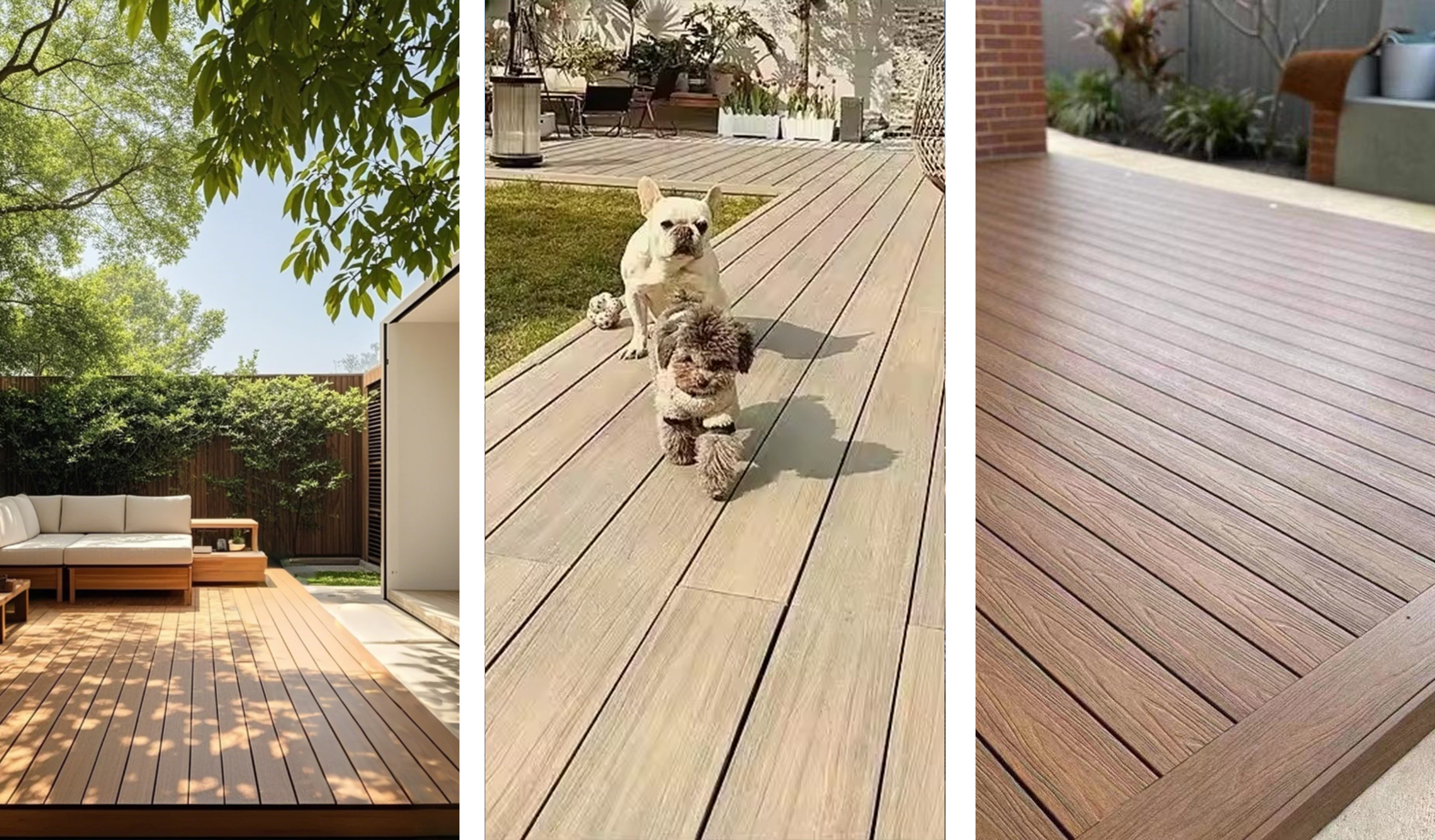

>> Application Scenarios

WPC (Wood Plastic Composite) co-extruded flooring is widely applicable due to its durability, environmental friendliness, and ease of maintenance

In the field of landscape architecture, it is commonly used for park pathways, scenic boardwalks, and riverside or coastal walkways.

In residential outdoor spaces: such as villa courtyards, balconies, terraces, rooftops, and areas around outdoor swimming pools.

In commercial and public areas: plazas, pedestrian streets, public rest zones, and community green decorations.

>> Side View:

WPC outdoor decking, also known as wood-plastic composite decking, is primarily made from wood flour, PE powder, and other additives. This type of board is produced through a series of processes including raw material mixing, extrusion molding, cooling and shaping, surface treatment, and processing. The co-extruded WPC products feature the natural color variations and grain of real wood, enhanced by a 360-degree full coverage of a polymer protective layer, which significantly improves the product's strength. Moreover, it ensures that the product can withstand the harsh conditions of outdoor environments, avoiding the various shortcomings associated with traditional solid wood and pressure-treated wood products.

Our wood-plastic co-extruded solid wood flooring is all covered with a 360-degree high-molecular composite protective layer technology. Avoid the defects of traditional solid wood such as mold, water cracking, discoloration, deformation and warping. The embossing process of 3D wood grain finish is not "thermal printing", but "embossing", so this wood grain can last for at least 8 to 10 years. It retains the plastic shell, so the surface is harder and absorbs less water. Because the surface is hard, scratches will not take effect on it

>> Product Benefits

Features of Wood-Plastic Co-Extruded Solid Flooring:

| Feature | Description |

|---|---|

| Dimensionally Stable | Long-lasting with a natural feel. |

| Temperature & Weather Resistant | Stable across a wide temperature range and resistant to weather conditions. |

| High Impact Resistance | Durable and able to withstand strong impacts. |

| Eco-Friendly | Environmentally friendly and recyclable. |

| Aesthetic Variety | Available in a wide range of colors to meet diverse design and aesthetic needs. |

| Easy Installation | Simple and straightforward to install. |

| Decay & Crack Resistant | Resistant to decay and cracking. |

| Moisture-Proof | Protects against moisture damage. |

>> Parameter

Product Name | WPC Co-Extrusion Soild Decking |

Constituent | HDPE,Wood powder,Additives |

Dimension | 137×23mm |

Length | 2.2m,2.2m,5.4m and can be customized. |

Surface treatment | Sanded&Brushed |

Our Colors | Walnut,beach,ash,cherryred,teak,dove grey,etc. |

>> Application Scenarios

WPC (Wood Plastic Composite) co-extruded flooring is widely applicable due to its durability, environmental friendliness, and ease of maintenance

In the field of landscape architecture, it is commonly used for park pathways, scenic boardwalks, and riverside or coastal walkways.

In residential outdoor spaces: such as villa courtyards, balconies, terraces, rooftops, and areas around outdoor swimming pools.

In commercial and public areas: plazas, pedestrian streets, public rest zones, and community green decorations.